Global warming is one of the most significant issues in the world. Addressing the challenges posed by climate change has become an international consensus. As a leading company in the dairy industry, sustainable development is our commitment to stakeholders and has also become our core competitive strength in the market. In 2021, Yili committed to achieve carbon neutrality by 2050, becoming the first company in China's food industry to set carbon neutrality target. Yili has been actively working to decrease our greenhouse gas emissions through both technological measures and improved management practices. We have also consistently dedicated ourselves to assisting suppliers in effectively reducing their energy consumption in order to achieve the goal of lowering greenhouse gas emissions. This collaboration not only aids in environmental improvement but also encourages the entire supply chain to evolve towards greater sustainability. We hope that through our efforts, we can provide good examples and references for others.

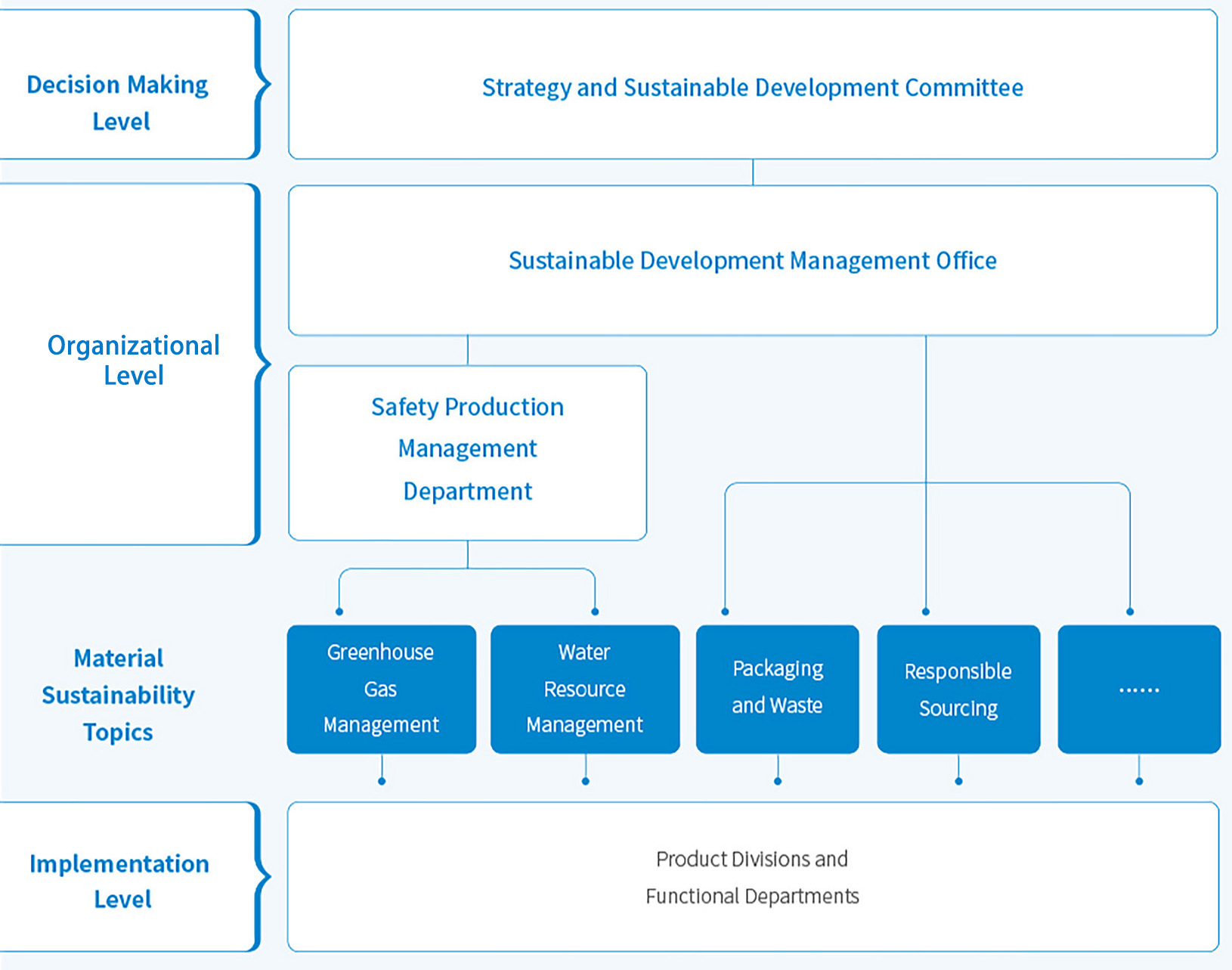

Yili has established a Strategy and Sustainable Development Committee at the board level, which is composed of eight directors (including two independent directors), under the charge of Mr. Pan Gang, the Chairman and President of Yili. Apart from business development strategy, the Committee also focuses on researching and recommending sustainability strategic plans for Yili's long-term development. The Committee also oversees its sustainability strategy implementation across the company (including greenhouse gas management). The Sustainable Development Office is under Strategy and Sustainable Development Committee, which is responsible for the sustainability performance supervision and report to the Strategy and Sustainable Development Committee on a regular basis. The Safety Production Management Department of Yili is responsible for day-to-day management of GHG emissions. The department has a dedicated Carbon Management Director responsible for offering technical support for executing the GHG reduction project across Yili's different business units. The quarterly progress reports are submitted to the Sustainable Development Management Office for review and monitoring purposes.

In order to achieve the goal of carbon neutrality by 2050, Yili released its Carbon Neutral Plan in 2022, named "Zero-Carbon Future Plan of Yili Group". This plan provides a strategic carbon reduction roadmap and detailed guidance for carbon reduction.

Structuring Yili's high-quality development plans.

Refining Yili's development strategy and principles

Considering carbon peak and carbon neutrality into Yili's business development

Announcing carbon peak achievement in 2012

Achieving carbon neutral by 2050

2012

The base line year for setting up Yili's emission reduction targets

2021

A preliminary green, low-carbon and circular development business model is formed, with energy efficiency greatly improved

2030

Achieve significant progress in "green" transition across the entire supply chain, bringing operation energy consumption efficiency to world's leading level

2040

Achieve high level of low-carbon and circular development; the energy consumption efficiency of our entire supply chain meet the highest international standards

2050

Carbon neutrality throughout the whole supply

In addition to achieving the ultimate goal of "carbon neutrality" by 2050, our "Zero-Carbon Future Plan of Yili Group" also establishes several milestone targets. Some targets and their progress made in 2024 are as follows:

| Target Categories | Target Value | Progress made in 2024 | Target Progress |

|---|---|---|---|

| Carbon emission intensity reduction | By 2030, the carbon intensity per ton of products will be reduced by 50% compared with 2012. | Reduced by 59.83% | Achieved |

| Coverage of measuring Scope 3 carbon emissions | By 2025, the carbon footprint verification for all core raw milk suppliers? will be completed. | 100% completed | Achieved |

| By 2030, the carbon footprint verification for all core suppliers of raw and auxiliary material will be completed. | 47.2% completed | In progress | |

| Targets on supply chain carbon emissions reduction | By 2030, the carbon intensity of core raw milk suppliers will be reduced by 35% compared with 2021. | Reduced by 23.66% | In progress |

| The carbon intensity of low-carbon transition suppliers? will be reduced by 7% by 2030, with 2021 as the base year. | Reduced by 3.94% | In progress |

*? Core raw milk suppliers: it refers to suppliers demonstrating excellence in price competitiveness, quality assurance, delivery reliability, technical support, service responsiveness, asset management, process optimization, and workforce management, including ranches that Yili holds majority or partial ownership. *? Low-carbon transition suppliers: it refers to suppliers committed to carbon inventory, implementing emissions reduction initiatives, and advancing toward carbon neutrality through operational transformations.

Yili has assessed the GHG emissions for the life cycle of all 8 core category products in accordance with the ISO 14067:2018 standard. The assessments cover the planting, breeding, transport, production, and disposal stages of the products.

Carbon emissions from production of Tier 1 raw and auxiliary materials?

Carbon emissions from production of Tier 2 raw and auxiliary materials?

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from product storage

Carbon emissions from waste disposal

Carbon emissions from production of Tier 1 raw and auxiliary materials

Carbon emissions from production of Tier 2 raw and auxiliary materials

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from product storage

Carbon emissions from waste disposal

Carbon emissions from production of Tier 1 raw and auxiliary materials

Carbon emissions from production of Tier 2 raw and auxiliary materials

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from product storage

Carbon emissions from waste disposal

Carbon emissions from production of Tier 1 raw and auxiliary materials

Carbon emissions from production of Tier 2 raw and auxiliary materials

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from product storage

Carbon emissions from waste disposal

Carbon emissions from production of Tier 1 raw and auxiliary materials

Carbon emissions from production of Tier 2 raw and auxiliary materials

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from product storage

Carbon emissions from waste disposal

Carbon emissions from production of Tier 1 raw and auxiliary materials

Carbon emissions from production of Tier 2 raw and auxiliary materials

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from product storage

Carbon emissions from waste disposal

Carbon emissions from production of Tier 1 raw and auxiliary materials

Carbon emissions from production of Tier 2 raw and auxiliary materials

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from product storage

Carbon emissions from waste disposal

Carbon emissions from production of Tier 1 raw and auxiliary materials

Carbon emissions from production of Tier 2 raw and auxiliary materials

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from product storage

Carbon emissions from waste disposal

Carbon emissions from raw materials acquisition and transportation

Carbon emissions from production of products

Carbon emissions from transportation

Carbon emissions from waste disposal

*? Tier 1 raw and auxiliary materials suppliers: the direct suppliers *? Tier 2 raw and auxiliary materials suppliers: the indirect suppliers

Step up energy efficiency retrofits

The demonstrative milk production plant is located in the heart of Yili Modern Intelligent Health Valley. The aim of the plant is to establish a global manufacturing benchmark in terms of scale, automation, technology, and carbon emissions. The project applies the most advanced technology in thermal energy recycling in aspects such as architectural design, energy circulation, production processes, and logistics storage. It can save 5,329 tons of standard coal annually and reduce carbon emissions by 41,895 tons. The daily energy savings are equivalent to the daily electricity usage of 930 households.

The wastewater treatment plant at the Weifang Yili Dairy Factory has an annual carbon emission of approximately 4,200 tonnes. In 2022, the factory achieved 'carbon neutrality' through various pollution and carbon reduction initiatives including biogas recycling, air blower replacement, sludge minimization, methane utilization, and distributed solar power generation, etc. These upgrades reduced approximately 4,284 tonnes of carbon emissions and saved RMB 640,000 in electricity costs and RMB 1,160,000 in steam costs, respectively.

Clean energy utilization

In March 2023, Longyou Yili Dairy Factory successfully connected its 5.77 MW distributed photovoltaic power station to the grid.It is the largest distributed photovoltaic installation in China's dairy industry. The project includes an energy management platform, has integrated 20 energy management sub-systems, and has 554 monitored indicotors. Annually, the project reduces energy costs by more than 2 million RMB and reduced carbon emissions by 3,050 tons of CO?e.

Yili Yunnan Factory obtained a 'Green Electricity Certificate' in 2021, issued by the Kunming Power Exchange Center, for purchasing renewable energy from Yunnan Province. It is the first such certificate in China's dairy industry. In 2022, by purchasing renewable energy and China Certified Emission Reductions (CCER) credits, the Yili Yunnan Factory became the first Yili factory to achieve carbon neutrality.

Supply chain carbon reduction

Youran Dairy is a core raw milk supplier for Yili. In 2023, Yili launched a carbon reduction cooperation project with Youran Dairy. The project primarily includes the application of a liquid manure return system, promotion of liquid manure return practices, and the adoption of methane gas recovery and utilization technology. By replacing chemical nitrogen fertilizers with organic fertilizers, the project aims to reduce the usage of nitrogen fertilizers, improve soil quality, and decrease greenhouse gas emissions. As of 2023, Youran Dairy has initiated biogas projects at 9 farms, with 7 farms already in operation. Each farm can produce up to 5 million cubic meters of biogas annually, with an approximate annual electricity generation of 8 million kWh. Youran Dairy has also introduced an intelligent integrated manure treatment system at 15 farms, which is expected to reduce greenhouse gas emissions by about 90,000 tons annually.

In 2024, Yili collaborated with packaging material suppliers to launch a carbon reduction project. In the logistics sector, Yili replaced traditional cardboard boxes with reusable crates for transporting pre-made cup yogurt, reducing paper usage and cutting carbon emissions by 2,352.67 tons. Additionally, Yili worked with packaging material suppliers to reduce the thickness of composite sheets used in the packaging of ambient cheese products, cutting down on plastic usage and successfully lowering carbon emissions by 818.25 tons.

Our People & Community

>Our Business

>